Application of Environmentally Friendly Technology in the Welding Process

DOI:

https://doi.org/10.62012/collaborate.v1i1.11Keywords:

welder, eco-friendly technology, competenceAbstract

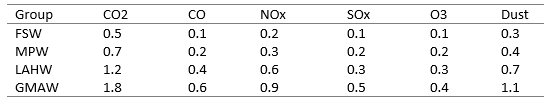

Environmentally friendly technology in the welding process is a technology that can optimize energy consumption, reduce emissions of harmful gases and particles, and minimize waste and radiation hazards. Environmentally friendly technology in the welding process can also affect the welder's competence, namely the welder's ability to perform welding by applicable standards and specifications. This article aims to analyze the effect of electrode variations in the SMAW welding process on the mechanical properties of ASTM A36 steel. ASTM A36 steel is a type of low-carbon steel widely used in steel construction. The electrodes used in this study were E6010, E6013, E7016, and E7018. These electrodes have different chemical compositions and current characteristics. This study uses a quantitative and experimental approach with a 4x3 factorial design. The results showed that the environmentally friendly technology used in the welding process affected the environmental performance and competence of the welder. FSW is the leading green technology regarding environmental performance and welder competence compared to MPW, LAHW and GMAW. This article can provide useful information for welders who want to improve their competence and meet international standards in the field of welding.

Downloads

References

H. Palippui, “Analysis Of The Installation Of Subsea Pipelines To Support The Need For Clean Water In Supporting Tourism Development On Kayangan Island”, Journal of Maritime Technology and Society, vol. 1, no. 1, pp. 1-9, Feb. 2022.